Our Design Process

How 24builds® Sets Come to Life

Every 24builds® set starts with an idea… and turns into a must-have for builders. Behind each model are hundreds of hours of hard work, obsessive attention to detail, and a clear mission: to make every piece tell a story. Here’s how we do it:

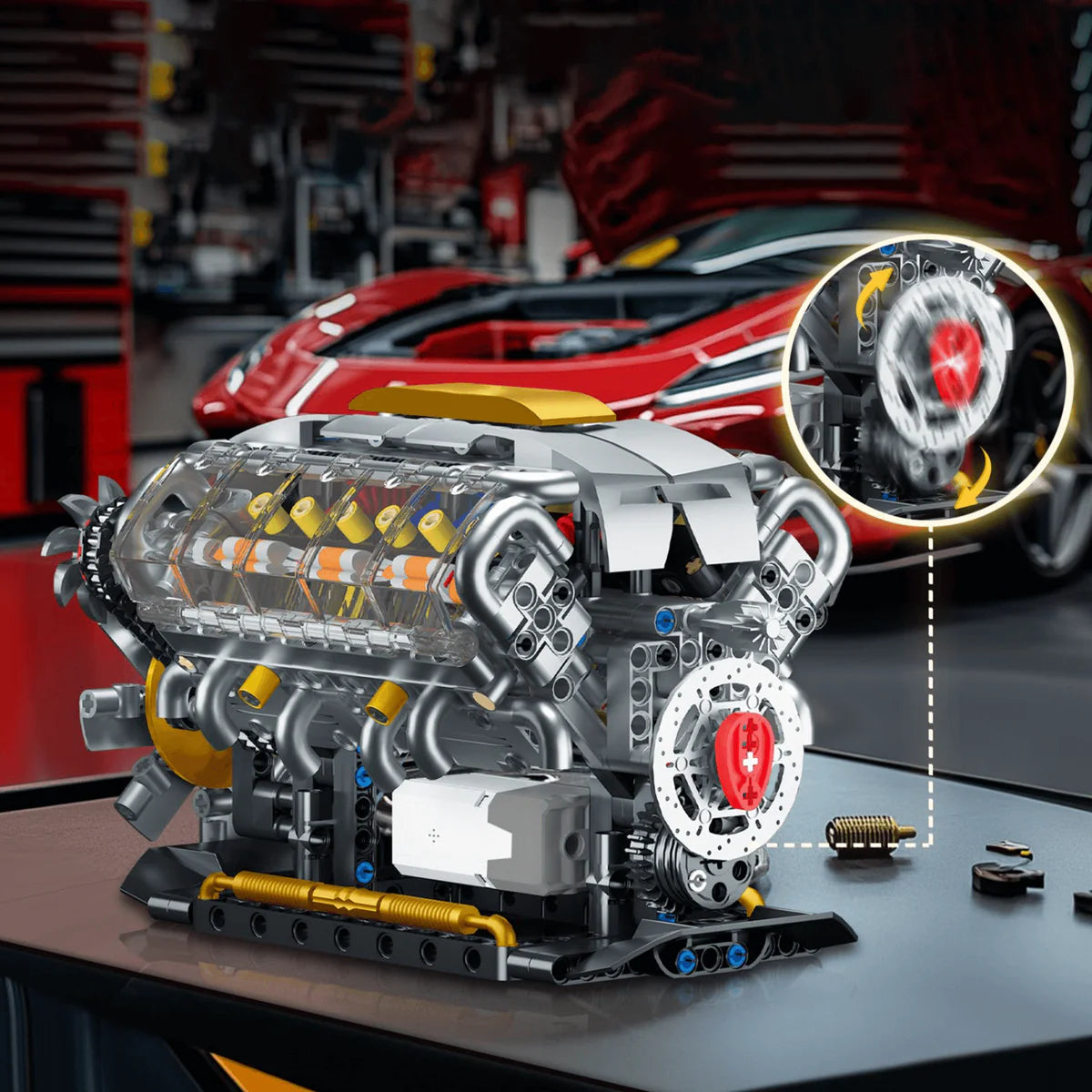

We're always listening—to our community, to trends, and to that spark of inspiration that can come from anywhere. Sometimes it’s an iconic vehicle, other times a striking building, an object full of personality, or something completely unexpected.

Once a concept stands out, we dive deep: gathering references, understanding its shapes and structure, and thinking about how it could come to life with bricks—both inside and out.

Fun fact: Some of our most loved builds were community suggestions that started with just one DM.

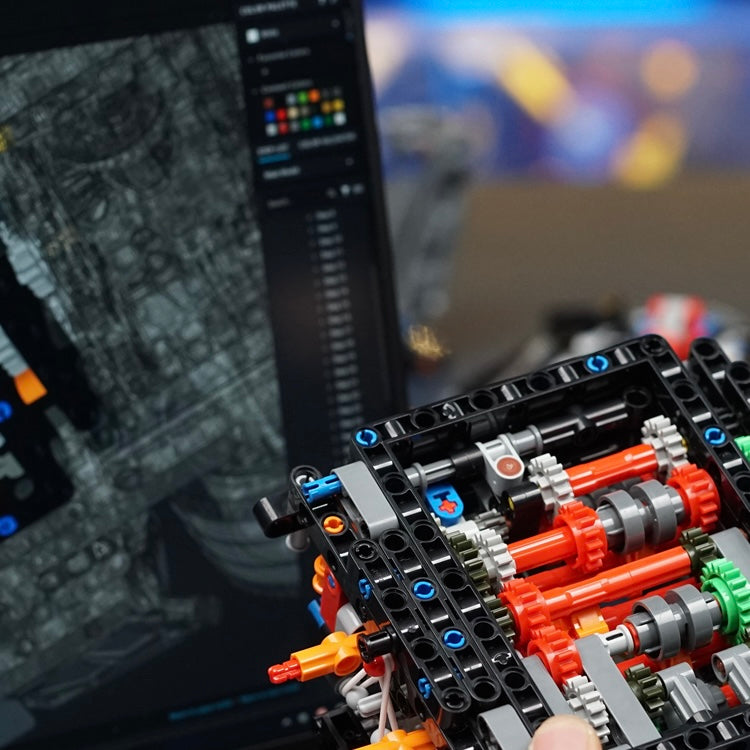

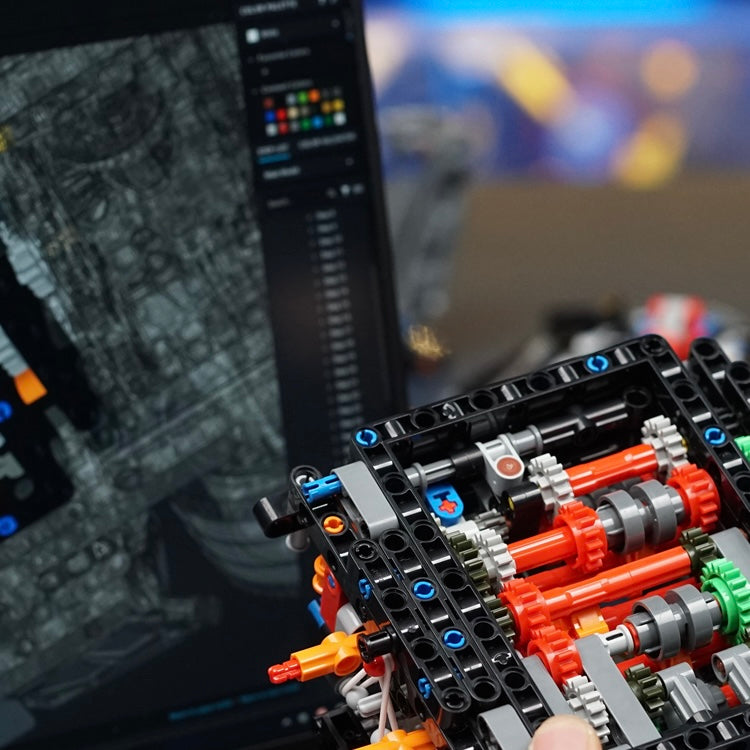

Our team of designers transforms each idea into a functional, beautiful model using advanced 3D software. During this step, we ensure that every angle works structurally and that the building process feels as fun as the final result looks.

Fun fact: Our largest models can take over 100 hours to design before even being tested in real life!

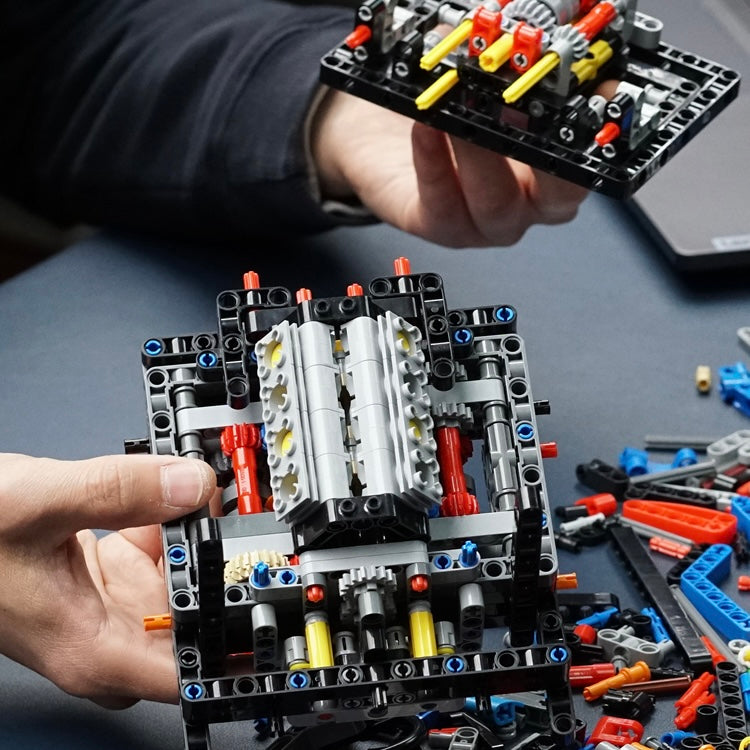

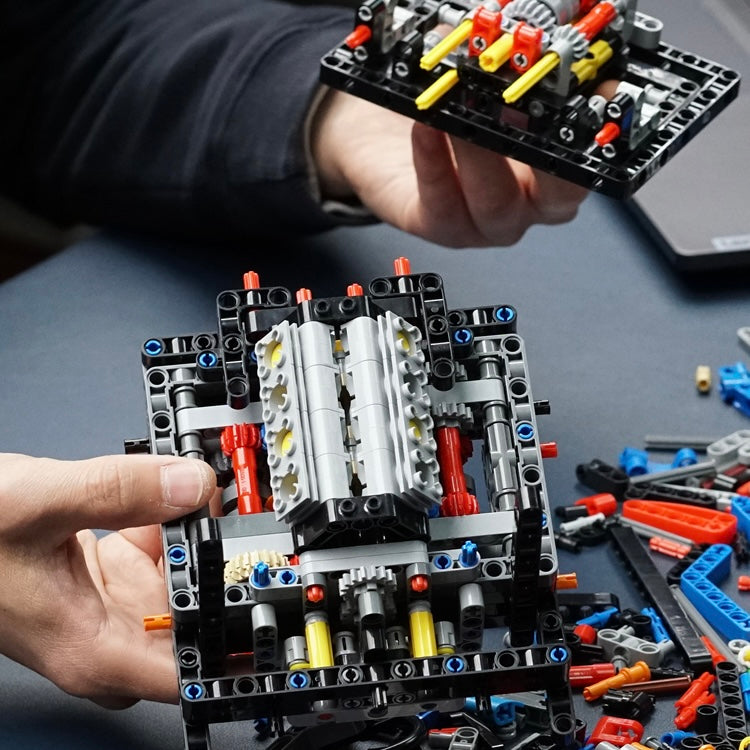

Once the digital version is ready, we build physical prototypes to check every detail. We tweak instructions, improve parts stability, and test for a smooth experience—whether you're a first-time builder or a brick veteran.

After final approval, we move into full production using high-quality bricks. Each set includes step-by-step instructions and arrives carefully packed, ready for you to enjoy. Every build you receive is the result of hundreds of decisions, tests, and refinements.

We're always listening—to our community, to trends, and to that spark of inspiration that can come from anywhere. Sometimes it’s an iconic vehicle, other times a striking building, an object full of personality, or something completely unexpected.

Once a concept stands out, we dive deep: gathering references, understanding its shapes and structure, and thinking about how it could come to life with bricks—both inside and out.

Fun fact: Some of our most loved builds were community suggestions that started with just one DM.

Our team of designers transforms each idea into a functional, beautiful model using advanced 3D software. During this step, we ensure that every angle works structurally and that the building process feels as fun as the final result looks.

Fun fact: Our largest models can take over 100 hours to design before even being tested in real life!

Once the digital version is ready, we build physical prototypes to check every detail. We tweak instructions, improve parts stability, and test for a smooth experience—whether you're a first-time builder or a brick veteran.

After final approval, we move into full production using high-quality bricks. Each set includes step-by-step instructions and arrives carefully packed, ready for you to enjoy. Every build you receive is the result of hundreds of decisions, tests, and refinements.